SheetRunner 1850 (73 in) Dual Rotary Sheeter

Product Description

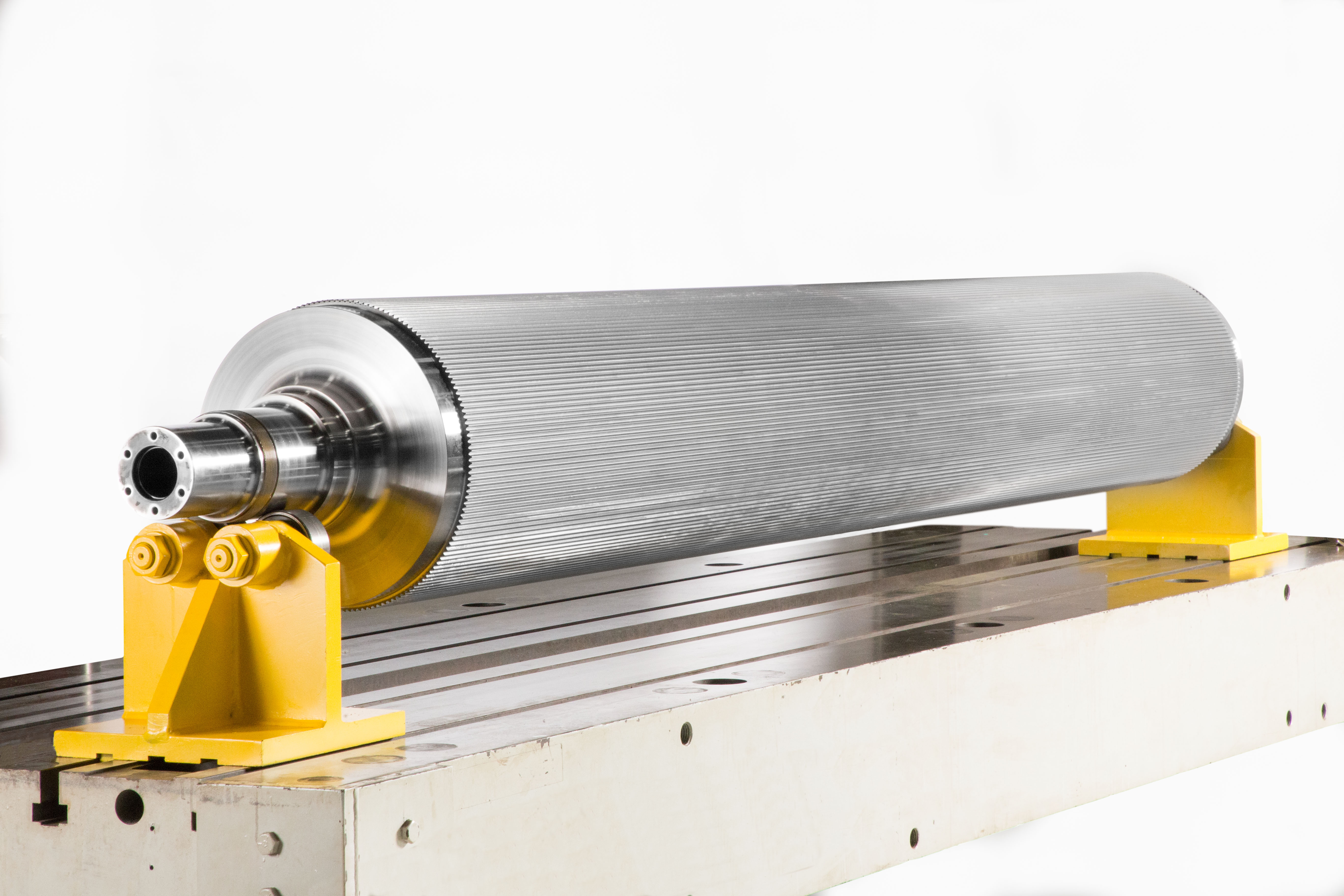

The SheetRunner is a dual-rotary sheeter, optimized for high-volume board production. This machine has been designed for folding carton plants and commercial printers. With brushless liquid-cooled high-torque knife cylinder motors, the sheeter offers reduced maintenance and lower power consumption.

Features

- Designed for high volume board production environments

- Standard run speed of 335 m/min (1100 ft/min) or optional 400 m/min (1500 ft/min)

- Dual rotary direct drive knife provides superior cut quality

- Brushless liquid-cooled Hi-torque knife cylinder motors for reduced maintenance and lower power consumption

- Optional mesh belt discharge conveyors for minimal stack disturbance allow removal by drive-on pallet jacks from any side

- Continuous operation at skid discharge for increased production

- Optional On-the-Fly Bowtie Splicer for decreased waste and increased production at roll change

- Plastic chain conveyor allows discharge of full skids without shifting the sheets and an electric pallet jack can be driven directly onto the conveyor

- IEC 61131-3 PC-based control system

- Available in 1850 mm

Product Features

Designed for folding carton plants and commercial printers, the SheetRunner is a dual-rotary sheeting system that is optimized for high-volume board production. Brushless liquid-cooled high-torque knife cylinder motors are used to reduce maintenance and lower power consumption.

Superior Knife Performance

Dual rotary direct drive knife provides superior cut quality.

Designed for High Volume Board Production

With a standard run speed of 335 m/min (1100 ft/min) or optional 400 m/min (1500 ft/min), the SheetRunner is ideal for demanding board production environments. Its continuous operation at skid discharge ensures increased production.

Splicer Option

Low Consumption & Noise Level

Brushless liquid-cooled Hi-torque knife cylinder motors for reduced maintenance, lower noise level and lower power consumption.

| Metric | Imperial | ||

|---|---|---|---|

| Sheet Width | max | 1850 mm | 73 in |

| Reel Width | max | 1700 mm 1900 mm | 67 in 75 in |

| Reel Diameter | max. optional | 1850 mm 2130 mm | 73 in 84 in |

| Reel Weight | max. | 4545 kg | 10000 lb. |

| Speed | max. | 400 m/min | 1100 ft/min |

| Length Accuracy | Single Web | + / - 0,38 mm (0.015 in) | |

| Length Accuracy | Multi Web | + / - 0,5 mm (0.020 in) | |

| Knife | max. | 1000 gsm | |

| Slitter | max. | 600 gsm | |

| Sheet Length | min. max. | 400 mm 2080 mm | 15.75 in 82 in |

SheetRunner 1850 (73 in) Dual Rotary Sheeter

Compare With

Superior Knife Performance

PC Based Controls

Superior Splicing

���˴�Ƭ' brand MarquipWardUnited is the world leader in splicer technology with over 5000 units installed around the world. The SheetRunner™ can be configured with the MarquipWardUnited Bow-Tie Splicer and MARQ II Roll Stand for continuous paper delivery system operation.

Standard Features

- Vibrating full width side tamps, integrated curling shoes, and modular backstop

- Heavy-duty lift table

- Vacuum-modulated overlap section

- Reject gate

- Available in widths of 1850 mm (73 in) and 2500 mm (98 in)

- Continuous skid discharge system with multiple conveyors for accumulation of full skids

- Multiple decurl systems including the Three Bar bi-directional decurler with programmable decurl on diameter control

MarquipWardUnited 73 in/1850 mm SheetRunner installed at Utah PaperBox plant

In 2020, our customer Utah PaperBox, Salt Lake City, UT, USA, installed a new MarquipWardUnited Sheet Runner at their plant. It's great to see how this dual rotary sheeter efficiently helps them cutting rolls into press-ready stacks of sheets.

Find Your Machine

���˴�Ƭ offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the ���˴�Ƭ equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)